Structure Analysis of Continuous Screen Changer for Twin Screw Extruder

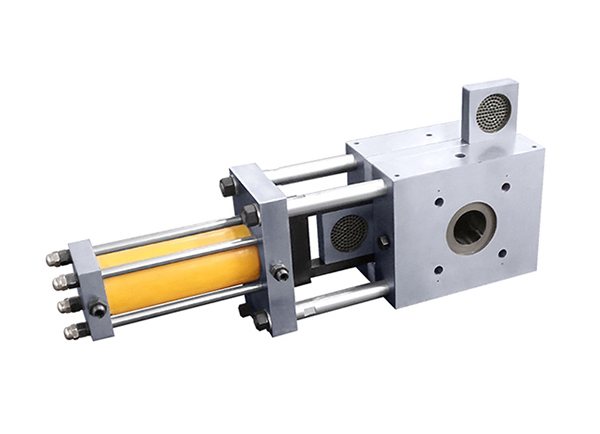

The continuous screen changer for twin-screw extruder is mainly composed of square slider, filter screen, high pressure oil cylinder, connecting piece, die head, extruder and connecting frame. Its structural feature is that round holes are set on both sides of the square slider, the depth of both sides of the round holes of the square slider is different, the deep side is used to place the filter screen, and the filter screen is cut to the size corresponding to the diameter of the round holes of the square slider, Stepped small holes are distributed in the round hole. The square slider is connected with the high-pressure oil cylinder. The high-pressure oil cylinder is used to push the sliding of the square slider. The die head and the extruder are connected by connecting pieces. A connecting frame is fixed at the connecting part between the fixed die head and the extruder. The connecting frame should be able to place three square sliders at the same time. One square slider is placed with a filter screen and is in use, The other one is used for preheating and waiting for replacement. The third one is that after use, the three square sliders are closely connected, and the square sliders in use are hidden in the connection part between the die head and the extruder.

The sealing design of the continuous screen changer for the new extruder with high wear resistance, high pressure resistance and high precision improves the effective filtering area and filtering effect. It can be used for all thermoplastic plastics such as sheet, plate, pipe, film covering, film blowing, wire, cable, profiled material, granulation, etc. It solves the problems existing in the old screen changer, such as: changing the filter screen will cause shutdown, waste of raw materials, affect the stability of production, the slider is not preheated before replacement, and it is inconvenient to replace. It does not need to stop the lower pelletizer, and directly pushes the slider to replace the filter screen through hydraulic assistance. The slider used is more convenient to use after preheating, greatly reducing the waste of raw materials, and effectively improving the production efficiency. info@battemachinery.com